Facial Prosthetics Lab

The Challenge

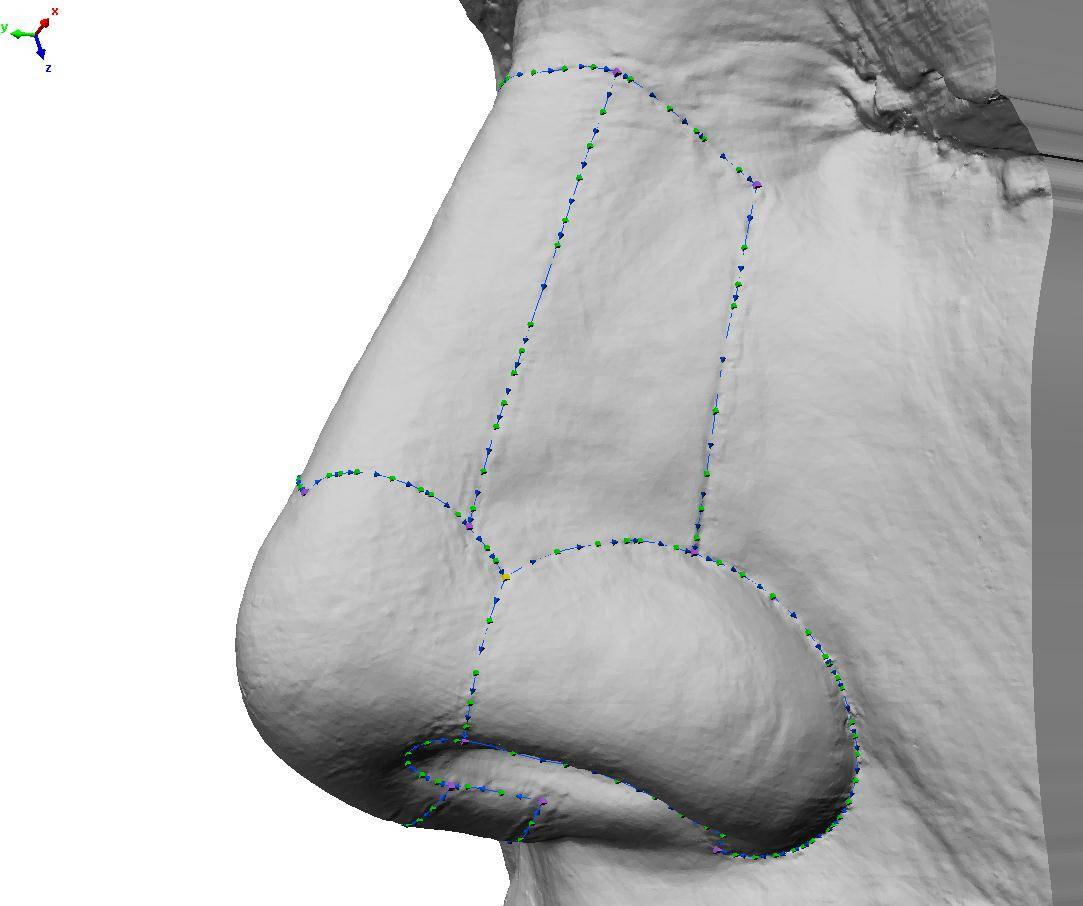

3D scanning for human medical devices, especially prosthetics is a particularly stimulating and rewarding sector of the business. The need is obvious, and humans have very similar forms but very different geometric expressions of those forms. Also despite the need there is not huge funding available for these devices. All of this points towards automation and process engineering to streamline the process as much as possible.

At Direct Dimensions we are lucky to have an in house facial prosthetics lab and a Johns Hopkins Facial Anaplastogist so we are able to refine these workflows quickly.

The Solution

Our pattern has been to develop these workflows manually in coordination with our resident expert and then slowly transition them into more automated workflows as time and demand allow. Turn around time is also a consideration as we have moved away from taking a cast and scanning and towards live scanning. We are currently in the beginning stages of developing an online portal to automate large portions of this process.

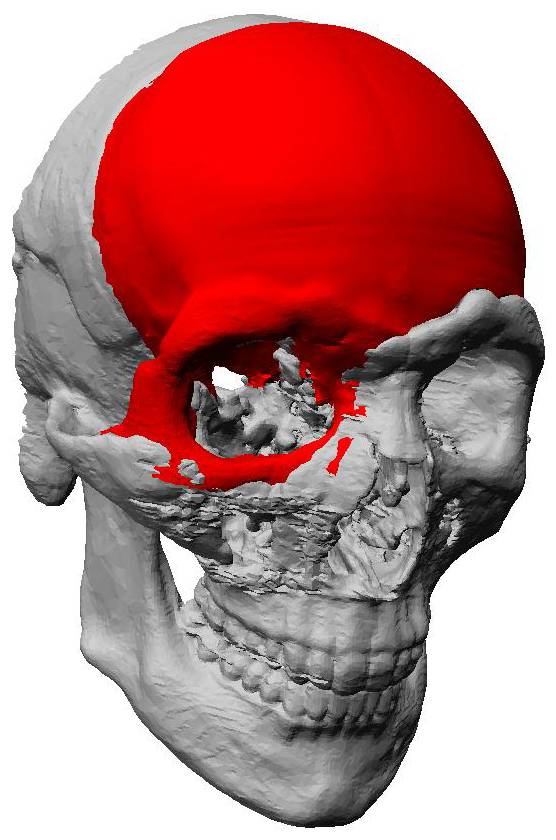

- Photogrammetry scanning of un-affected and / pr affected side

- Mirroring

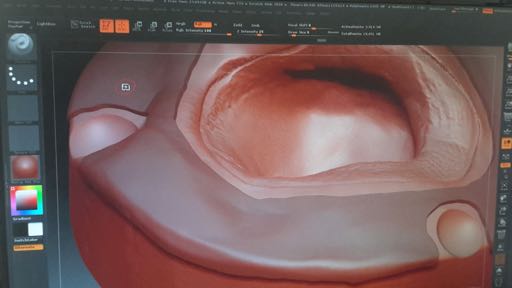

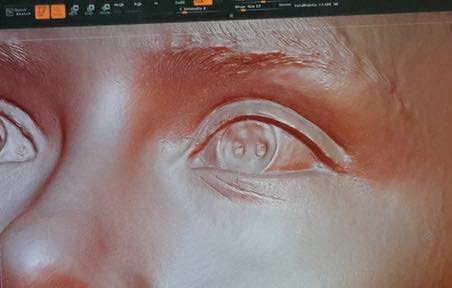

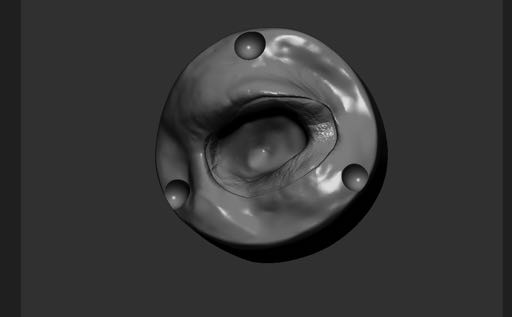

- Sculpting

- Pre for 3D printing

- 3D Printing

- At this point the 3D print is delivered to the artist so that he can complete the prosthetic using the 3D as the mold.